Shaping the Future: Plastic Trends in Fittings for 2025 and Beyond

Related Articles: Shaping the Future: Plastic Trends in Fittings for 2025 and Beyond

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to Shaping the Future: Plastic Trends in Fittings for 2025 and Beyond. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: Shaping the Future: Plastic Trends in Fittings for 2025 and Beyond

- 2 Introduction

- 3 Shaping the Future: Plastic Trends in Fittings for 2025 and Beyond

- 3.1 The Rise of Sustainability and Eco-Consciousness

- 3.2 Technological Advancements: Revolutionizing Fittings

- 3.3 Focus on Efficiency and Cost-Effectiveness

- 3.4 The Future of Plastic Trends Fittings: A Look Ahead

- 3.5 Related Searches:

- 3.6 FAQs about Plastic Trends Fittings

- 3.7 Tips for Selecting Plastic Trends Fittings

- 3.8 Conclusion

- 4 Closure

Shaping the Future: Plastic Trends in Fittings for 2025 and Beyond

The world of plumbing and construction is constantly evolving, and plastic trends fittings are at the forefront of this change. As we move towards 2025, the demand for innovative, sustainable, and cost-effective solutions is driving the development of new and improved fittings. This article delves into the key trends shaping the future of plastic trends fittings and explores the benefits they offer to both consumers and the industry.

The Rise of Sustainability and Eco-Consciousness

Sustainability is no longer a niche concern; it’s a core value driving consumer choices and industry practices. Plastic trends fittings are increasingly incorporating recycled materials and bio-based plastics to reduce their environmental footprint.

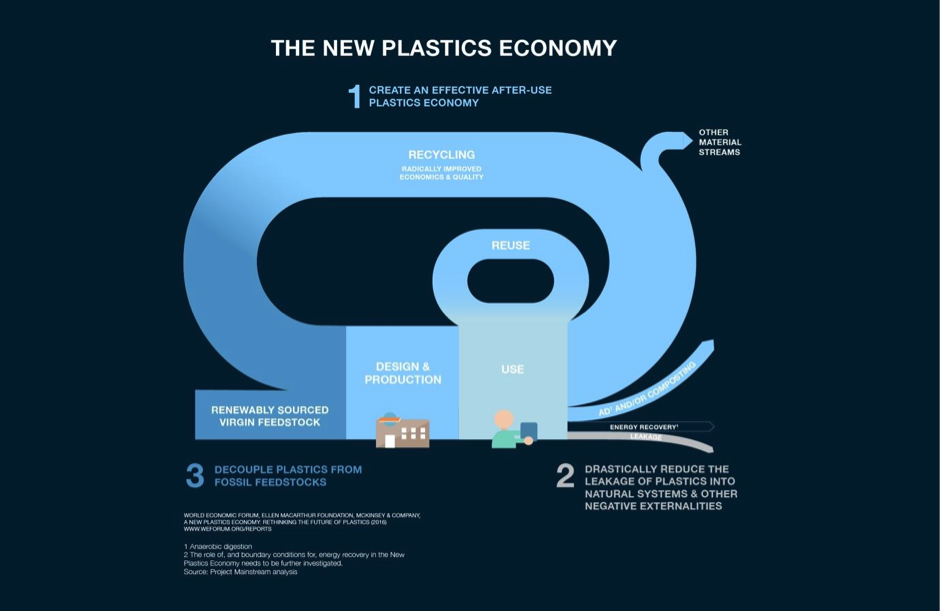

- Recycled Plastics: Manufacturers are actively exploring ways to utilize recycled plastic waste streams in the production of fittings. This not only reduces reliance on virgin materials but also minimizes landfill waste and promotes a circular economy.

- Bio-based Plastics: Derived from renewable sources like corn starch or sugarcane, bio-based plastics offer a sustainable alternative to traditional petroleum-based plastics. These materials are biodegradable, reducing their environmental impact at the end of their lifecycle.

Technological Advancements: Revolutionizing Fittings

Technological advancements are revolutionizing the design, functionality, and performance of plastic trends fittings.

- Smart Fittings: Integration of sensors and communication technologies is enabling the development of smart fittings that can monitor water usage, detect leaks, and even control water flow remotely. This enhances efficiency, saves water, and provides valuable insights into water consumption patterns.

- 3D Printing: Additive manufacturing, or 3D printing, is emerging as a powerful tool for producing customized and complex fittings. This technology allows for on-demand production, reducing lead times and minimizing waste.

- Advanced Materials: Research and development efforts are focusing on the creation of high-performance plastics that offer superior durability, resistance to chemicals, and temperature extremes. These advancements are expanding the applications of plastic trends fittings in demanding environments.

Focus on Efficiency and Cost-Effectiveness

The construction industry is always seeking ways to optimize efficiency and reduce costs. Plastic trends fittings are playing a crucial role in achieving these goals.

- Lightweight Design: Plastics offer a significant weight advantage over traditional materials like metal. This reduces transportation costs and simplifies installation, especially in large-scale projects.

- Ease of Installation: Plastic trends fittings are typically designed for quick and easy installation, minimizing labor costs and reducing project completion time.

- Corrosion Resistance: Plastics are inherently resistant to corrosion, eliminating the need for costly maintenance and replacement associated with metal fittings.

The Future of Plastic Trends Fittings: A Look Ahead

As we move further into the future, plastic trends fittings are expected to become even more sophisticated and integrated into the fabric of our built environment.

- Increased Integration with Building Management Systems: Plastic trends fittings will be seamlessly integrated with smart building management systems, providing real-time data and enabling intelligent control of water flow and usage.

- Personalized Fittings: The rise of 3D printing and customization technologies will allow for the creation of fittings tailored to specific project requirements, ensuring optimal performance and aesthetics.

- Focus on Circularity: The industry will prioritize closed-loop systems, where plastic trends fittings are designed for easy disassembly and recycling, minimizing waste and promoting a circular economy.

Related Searches:

The following related searches provide further insight into the dynamic world of plastic trends fittings:

- Plastic Pipe Fittings: This broad category encompasses a wide range of fittings used in plumbing, irrigation, and other applications. Understanding the different types of plastic pipe fittings is crucial for selecting the right components for specific projects.

- PVC Fittings: Polyvinyl chloride (PVC) is a widely used plastic material for fittings due to its durability, affordability, and ease of installation. This search explores the latest trends and advancements in PVC fittings.

- PPR Fittings: Polypropylene random copolymer (PPR) is another popular plastic material for fittings, known for its resistance to high temperatures and chemicals. Exploring PPR fittings reveals the latest innovations and applications.

- Plastic Fittings for Water Supply: This search focuses on fittings specifically designed for water supply systems, including residential, commercial, and industrial applications.

- Plastic Fittings for Drainage: Plastic trends fittings are increasingly used in drainage systems due to their lightweight, corrosion-resistant properties. This search explores the latest trends and challenges in drainage fittings.

- Plastic Fittings for Gas Supply: The use of plastic trends fittings in gas supply systems is gaining momentum, driven by their safety and cost-effectiveness. This search delves into the specific requirements and regulations governing plastic fittings in gas applications.

- Plastic Fittings for HVAC Systems: Plastic trends fittings are finding increasing applications in HVAC systems, particularly for ductwork and piping. This search explores the advantages and challenges of using plastic trends fittings in HVAC applications.

- Plastic Fittings for Industrial Applications: Plastic trends fittings are used in various industrial applications, including chemical processing, oil and gas, and food processing. This search explores the specific requirements and trends in industrial plastic trends fittings.

FAQs about Plastic Trends Fittings

-

What are the advantages of using plastic fittings over traditional metal fittings?

- Lightweight and Easy to Install: Plastics are significantly lighter than metals, making them easier to transport and install, especially in large-scale projects.

- Corrosion Resistance: Plastics are inherently resistant to corrosion, eliminating the need for costly maintenance and replacement associated with metal fittings.

- Cost-Effectiveness: Plastic fittings are generally more affordable than metal fittings, making them a cost-effective solution for various projects.

- Improved Insulation: Plastics offer better insulation properties than metals, which can be beneficial in applications where temperature control is critical.

-

Are plastic fittings durable enough for demanding applications?

- Advancements in plastic technology have led to the development of high-performance plastics that can withstand extreme temperatures, pressures, and chemical exposure. These materials are suitable for demanding applications in various industries.

-

Are plastic fittings safe for use in water supply systems?

- Plastic fittings used in water supply systems are rigorously tested and certified to ensure their safety and compliance with industry standards. They are designed to prevent leaching of harmful substances into the water supply.

-

What are the environmental benefits of using plastic fittings?

- Reduced Reliance on Virgin Materials: Manufacturers are increasingly utilizing recycled plastics and bio-based plastics, reducing their reliance on virgin materials and minimizing their environmental footprint.

- Biodegradability: Bio-based plastics offer a sustainable alternative to traditional petroleum-based plastics, as they are biodegradable and decompose naturally at the end of their lifecycle.

-

What are the future trends in plastic fittings?

- Smart Fittings: Integration of sensors and communication technologies will enable the development of smart fittings that can monitor water usage, detect leaks, and even control water flow remotely.

- 3D Printing: Additive manufacturing, or 3D printing, will allow for the creation of customized and complex fittings on demand, reducing lead times and minimizing waste.

- Circular Economy: The industry will prioritize closed-loop systems, where fittings are designed for easy disassembly and recycling, promoting a circular economy.

Tips for Selecting Plastic Trends Fittings

- Identify the Application: Clearly define the specific application for the fittings, considering factors like pressure, temperature, chemical resistance, and flow rate.

- Choose the Right Material: Select the appropriate plastic material based on the application requirements. PVC, PPR, and other specialized plastics offer different properties and suitability for various applications.

- Consider the Installation Method: Choose fittings that are compatible with the installation method and the existing plumbing system.

- Check for Certifications: Ensure the fittings meet relevant industry standards and have the necessary certifications for safety and performance.

- Source from Reputable Suppliers: Purchase fittings from reputable manufacturers and suppliers who offer quality products and reliable customer support.

Conclusion

Plastic trends fittings are playing a pivotal role in shaping the future of plumbing and construction. Driven by sustainability, technological advancements, and a focus on efficiency, plastic trends fittings are offering innovative solutions that are both environmentally responsible and cost-effective. As we move towards 2025 and beyond, we can expect to see even more sophisticated and integrated plastic trends fittings that enhance our built environment and contribute to a more sustainable future.

Closure

Thus, we hope this article has provided valuable insights into Shaping the Future: Plastic Trends in Fittings for 2025 and Beyond. We thank you for taking the time to read this article. See you in our next article!